Non-Woven Bags: Sustainable Carriers for a Greener Tomorrow

Introduction: As the world strives for a more sustainable future, non-woven bags have emerged as a revolutionary solution to replace conventional plastic bags. These versatile, environmentally friendly bags have gained attention for their durability, reusability, and eco-conscious production methods. This article delves into the distinctive features, benefits, and manufacturing processes of non-woven bags, highlighting their pivotal role in reducing plastic waste and promoting responsible consumer choices.

The Environmental Significance of Non-Woven Bags: Non-woven bags are crafted by bonding long fibers together through mechanical, thermal, or chemical processes. Unlike plastic bags that contribute to pollution, non-woven bags are biodegradable and easily recyclable. Their robustness ensures a longer lifespan, reducing the need for frequent replacements and minimizing waste generation.

Key Attributes and Benefits:

Exceptional Strength and Durability: Non-woven bags are engineered to carry heavy loads, making them a reliable option for various purposes, from grocery shopping to daily errands.

Eco-Friendly Composition: Constructed from natural fibers or recyclable synthetics, non-woven bags have a lower environmental impact. They gradually break down, alleviating stress on landfills and marine ecosystems.

Sustainable Reusability: The durability of non-woven bags allows for multiple uses, reducing the demand for single-use plastics. They can be easily washed, ensuring cleanliness and extended use.

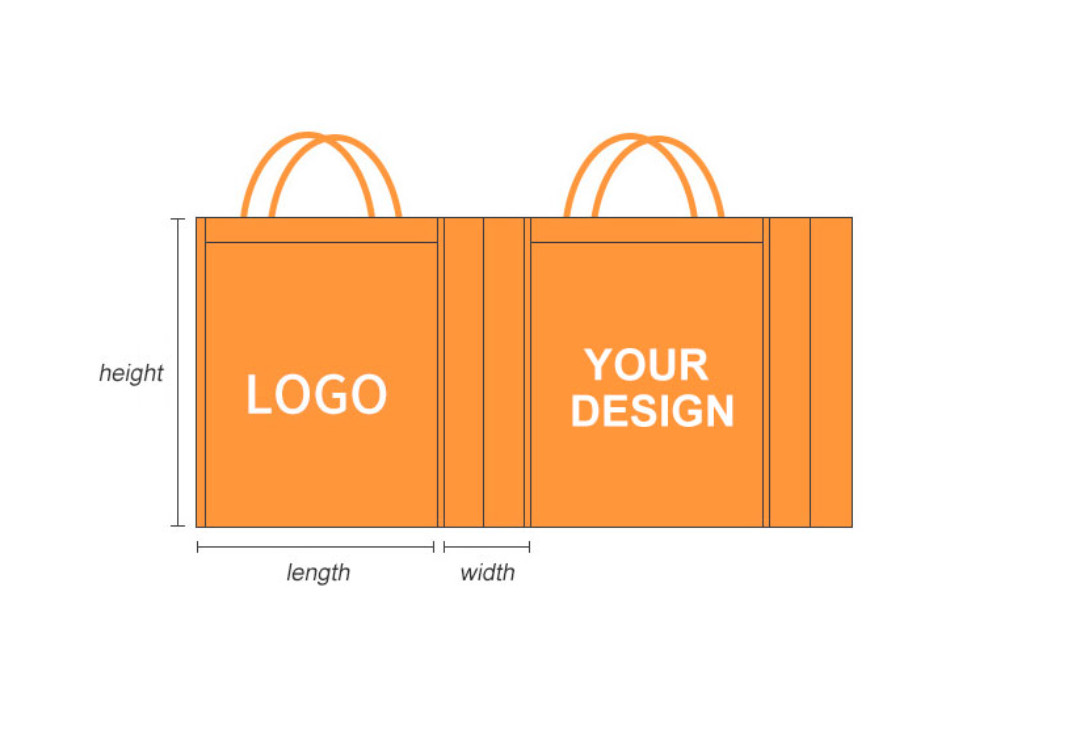

Personalized and Practical: Non-woven bags can be customized with an array of colors, sizes, and designs, merging functionality with aesthetics.

Economically Sound Choice: While non-woven bags might have a slightly higher initial cost, their extended lifespan translates to long-term savings, surpassing the short-lived nature of plastic bags.

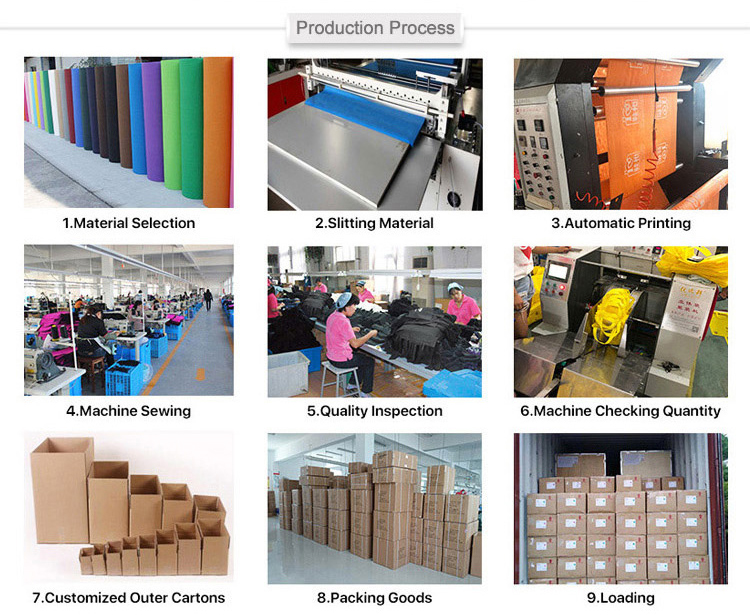

The Intricate Manufacturing Process: The production of non-woven bags involves a series of meticulous steps:

Web Formation: Long fibers are intricately arranged to create a web-like structure using techniques such as spinning, carding, or air-laid methods.

Bonding: These fibers undergo mechanical (needle punching), thermal (heat bonding), or chemical (adhesive bonding) processes to achieve structural coherence.

Precision Cutting and Shaping: The bonded fabric is accurately cut and shaped into the desired bag dimensions.

Artistic Expression and Finishing: Intricate designs are printed using eco-friendly inks. The bags are then equipped with handles, zippers, or other functional closures.

Empowering Sustainable Choices: By opting for non-woven bags over disposable plastics, individuals actively contribute to a cleaner environment. Retailers that offer non-woven bags showcase their commitment to sustainability, raising awareness about the collective responsibility to protect our planet.

Conclusion: Non-woven bags stand as a testament to the fusion of durability and environmental consciousness in the world of carrying solutions. Their innovative production methods, coupled with their resilience, reusability, and recyclability, position them as essential tools in addressing plastic waste and embracing a more sustainable future. By choosing non-woven bags, you take a conscious step towards safeguarding the planet for current and future generations, all while making a practical and stylish statement.